Scenario-Based Technoeconomic and Life-Cycle Analyses of Biomass Conversion Technologies

Authors:

Blake A. Simmons1* ([email protected]), Nawa Baral1, Aindrila Mukhopadhyay1, Steve Singer1, Taek Soon Lee1, John M. Gladden2, Alberto Rodriguez2, Hemant Choudhary2, Henrik Scheller1, Patrick Shih3, Corinne D. Scown1, and Jay D. Keasling1,2

Institutions:

1Lawrence Berkeley National Laboratory; 2Sandia National Laboratories; and 3University of California–Berkeley

URLs:

Goals

The vision of Joint Bioenergy Institute (JBEI) is that bioenergy crops can be converted into economically viable, carbon-neutral, biofuels and renewable chemicals currently derived from petroleum, and many other bioproducts that cannot be efficiently produced from petroleum.

Abstract

Cellulosic biofuels have not yet reached cost parity with conventional petroleum fuels. One of the central approaches used at JBEI to identify promising biofuels and bioproducts, and the conversion technologies capable of producing them, is combining technoeconomic and life-cycle analysis. At JBEI, researchers have developed scenario-based methodologies to conduct this work. This poster will present findings from three of these scenarios: (1) engineering bioenergy crops to generate value-added bioproducts in planta can reduce input requirements relative to microbial chassis and skip costly deconstruction and conversion steps (Yang et al. 2022; Yang et al. 2020), (2) presents detailed process configurations for the bioadvantaged sustainable aviation fuel, dimethycyclooctane (DMCO) production to estimate the minimum selling price and life-cycle greenhouse gas (GHG) footprint considering three different hydrogenation catalysts and two bioconversion pathways (Baral et al. 2021), and (3) evaluation of protic and aprotic ionic liquids for the deconstruction and conversion of mixed woody biomass feedstocks using a one-pot configuration (Achinivu et al. 2022). This work provides new insights into the tradeoffs, challenges, and opportunities present in the advanced biomass conversion technologies being developed at JBEI realized at the commercial scale.

Image

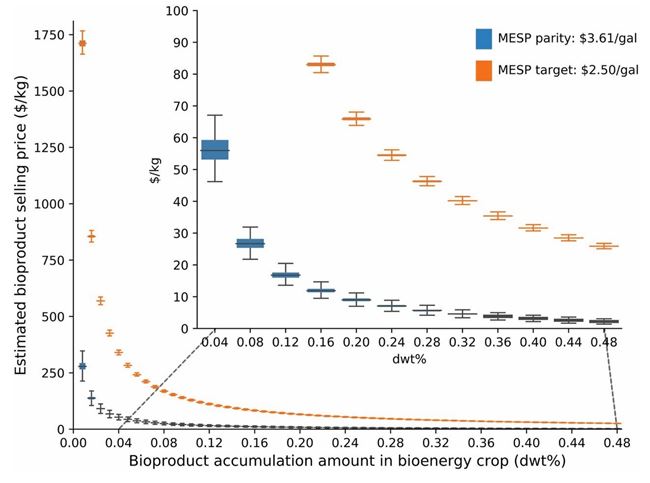

Minimum required selling price ranges for bioproducts ($/kg) under different in planta accumulation amount (dry basis) in order to reach the MESP parity ($3.61/gal) and targeted selling price of ethanol ($2.50/gal). The Inset shows the estimated bioproduct selling price of less than $100/kg (Yang et al. 2020).

References

Yang, M., et al. 2022. “Comparing in Planta Accumulation with Microbial Routes to Set Targets for a Cost-Competitive Bioeconomy.” PNAS 119(30), e2122309119. DOI: 10.1073/pnas.2122309119.

Yang, M., et al. 2020. “Accumulation of High-Value Bioproducts in Planta can Improve the Economics of Advanced Biofuels.” PNAS 117(15), 8639–48. DOI: 10.1073/pnas.2000053117.

Baral, N. R., et al. 2021. “Production Cost and Carbon Footprint of Biomass-Derived Dimethylcyclooctane as a High-Performance Jet Fuel Blendstock.” ACS Sustainable Chemistry & Engineering 9(35), 11872–82. DOI: 10.1021/acssuschemeng.1c03772.

Achinivu, E. C., et al. 2022. “In Situ Synthesis of Protic Ionic Liquids for Biomass Pretreatment.” ACS Sustainable Chemistry & Engineering 10(37), 12090–98. DOI: 10.1021/acssuschemeng.2c01211.

Funding Information

This work was part of the DOE Joint BioEnergy Institute (www.jbei.org) supported by the U.S. Department of Energy, Office of Science, Office of Biological and Environmental Research, through contract DE-AC02-05CH11231 between Lawrence Berkeley National Laboratory and the U. S. Department of Energy.